Palm Oil Story

Overview

Our palm oil supply chain

We are committed to transparency to ensure stakeholders are able to monitor our progress and hold us accountable. We believe transparency and traceability are fundamental in supply chain transformation, which is why we publish lists of our suppliers. This means we publish a list of palm oil mills in our supply chain. It also includes our tier-1 suppliers (PDF 116.26 KB), the palm oil companies we have a direct commercial relationship with, and their refineries and facilities (PDF 247.02 KB).

Farmers & plantations

The critical first mile

Smallholder-centric sustainability

To drive real change in the industry, our strategy aims to go beyond relying on the existing limited certified supply base (where, in some cases, we are not always able to gain full traceability), and move to purchase volumes that we can be sure are deforestation-free. We are focused on engaging a section of the industry that has been largely left out of the sustainable supply chain - independent mills and their smallholder supply base.

No credible plan for the transformation of the industry can ignore the pivotal role of independent smallholders who are generally unsupported and have no permanent ties to a larger plantation or mill. They often have low productivity and low-quality trees, and cannot afford technical advice to improve the situation, which puts more pressure on forests. Any credible sustainability plan for palm oil must take into account the needs of smallholders. Working with independent mills and smallholders means we can help the industry achieve higher levels of sustainability, traceability and transparency - and we gain more visibility within our supply chain.

We have deliberately moved closer to sourcing from independent smallholders in Indonesia and Malaysia, where our sourcing is greatest. Since 2016, we have supported more than 21,000 independent smallholders through various training programmes to implement good agriculture practices to increase their productivity sustainably, helping them raise their incomes while also building a source of high-quality sustainable palm oil for us. We also provide training in how to boost incomes, and in other areas of running a business, such as management and accountancy skills.

We offer support through certification, landscape initiatives and our new smallholder hubs, providing training to bring smallholders to certification and beyond. We aim to support another 40,000 smallholders with training through three new hubs in Aceh, North Sumatra, and Riau province of Indonesia; in 2023, we began work with the first groups.

Engaging with smallholders is a process. To learn more about them, we work with trusted partners - such as Fortasbi, IDH, Koltiva, Kompasia, Konservasi Indonesia, Meridia, SNV, Widya Erti Indonesia, and the World Resources Institute - to meet the communities living in the supply shed of our supplier mills. With the farmers' consent, our partners create polygon maps of the smallholdings and find out about the quality of the trees and soil, the challenges the farmers face, and their family situation. This information helps us understand how best to support them and also helps unlock the value of land for smallholders. So far, we have mapped 28,000 independent smallholders.

We help farmers with the various legal documents needed to obtain certification. These documents can also help farmers access credit or grants to replace their oil palms. Replanting is expensive, but it can increase production significantly and boost the supply of sustainably produced palm oil in the market. We have supported more than 8,200 independent smallholders to obtain certification from the Roundtable on Sustainable Palm Oil (RSPO), and continue to be one of the largest buyers of Independent Smallholder (ISH) RSPO credits, with more than 100,000 ISH credits purchased in 2023, providing valuable additional income for these farmers.

Supporting large-scale concessions and plantations

The majority of our palm oil sourcing comes from large-scale concessions and plantations, which were established before our no-deforestation requirements. We embed the principles of our People & Nature Policy into supplier contracts and collaborate with large and medium-sized plantations to help them put in place the sustainability policies and practices they need to comply.

For example, since 2018, we have worked with PT Perkebunan Nusantara (PTPN), the Indonesian government-owned plantation company and a significant supplier of palm oil to Unilever. We provide resources, funding and technical expertise to help PTPN obtain RSPO certification for its plantations and mills across Sumatra. And we support smallholders in its supply chain to meet our sustainability commitments.

Traders

Traceability: innovations for sustainability

Traders are an integral part of the palm oil supply chain. They are intermediaries who buy fresh fruit bunches from independent smallholders and sell them on, either to other traders or to mills. Farmers leave their fruit at collection points, often informal and some distance from their land, where it is picked up by traders, who often mix it with the fruit of other farmers. It is then difficult to know whether the fruit was produced sustainably.

Exploring cutting-edge technology with Premise and PemPem

We have explored cutting-edge technology to create traceability and understanding of this link in the supply chain. We successfully trialled a crowdsourcing app designed by our partner Premise, which allows anyone with access to a smartphone and the Premise app, including mill workers and suppliers, to upload photos and information about collection points. Knowing where the collection points are helps us to understand the link between independent mills and smallholder locations where the palm oil we use is grown, and it helps us to take action.

We are also delighted to have signed a contract with innovator PemPem in 2023. The company designed an app and ecosystem to digitise transactions of fresh fruit bunches produced by independent smallholders and capture material flow in the first mile. This model helps create a more traceable supply chain for Unilever and supports smallholders to obtain fairer prices and greater access to the palm market.

PemPem supports Unilever to gain greater traceability in the palm oil supply chain. It acts as a market-maker for onboarded smallholders with bids for fresh fruit bunches from mills. It then carries out the transaction and hires the traders to deliver the fruit to the mill. PemPem has begun onboarding the first batch of ten mills and 10,000 smallholder farmers in Riau and North Sumatra for Unilever, and traded volumes are expected to grow rapidly over 2024.

Mills

Sustainability initiatives

As buyers of fresh fruit bunches, the independent and integrated mills in our supply chain play a key role in ensuring palm oil is sustainably produced. We have supported more than 50 mills with training to help them understand and implement responsible sourcing and production practices.

We help mills to implement best management practices, including from the RSPO for managing peat, and from the High Carbon Stock Approach toolkit, an initiative to identify and protect forests.

When we onboard a mill into our supply chain, we work together to establish a sustainability roadmap, which we then embed into their contract. We aim to build their capacity to meet the sustainability standards of our People & Nature Policy, to adopt technology and partner in our smallholder programmes, to report on their deforestation-free supply chain, and perhaps to obtain certification.

We require independent mills to provide supply chain information linking us to where they obtain their fresh fruit bunches. We ask these mills to participate in various technology partnerships that we believe will unlock more visibility in the first mile of the supply chain. This accelerates the processes that lead us to sustainable palm oil: mapping the smallholders, and providing training in good agricultural practices and in creating additional livelihoods, which helps them to increase their incomes, thereby reducing pressure on forests.

Refineries

Engaging with refineries

We engage at all levels of the supply chain. Our contracts with refineries and facilities, our direct suppliers, require that they abide by our People & Nature Policy, or have their own equivalent sustainability policy in place, and provide us with a list of their supplier mills.

Each refinery or facility that directly supplies Unilever's factories needs to comply with our Responsible Partner Policy (PDF 4.45 MB), which sets out our requirements on ethical business, human rights and the environment. The audit gives us an overview of our partners and helps us support any that need help in meeting our sustainability requirements.

Unilever Oleochemical Indonesia

Positive impact

We invested $360 million in building our own processing plant, Unilever Oleochemical Indonesia (UOI), in Sei Mangkei in North Sumatra province, which we opened in 2015. It enables us to buy directly from mills, rather than through intermediaries. This gives us greater oversight of our supply chain and ensures we can have a positive impact on people and nature in the areas we source from.

The mills buy from independent smallholders, and we have mapped 28,000 farmers in the UOI landscape. The mills also participate in our smallholder sustainability programmes, which include equipping farmers with the skills to negotiate directly with them. Increasing farmers' incomes can lessen their need to expand their farms, and they become allies in protecting and regenerating nature.

Unilever factories

Traceability to the end product

One solution helping us to achieve a more transparent and traceable supply chain is SAP Green Token. It allows us to build traceability of our raw materials, prove our claims more consistently, and create deforestation-free scores for our factories. It uses blockchain technology to create auditable material logs (containing unique characteristics such as sustainability attributes) as they pass through each stage of the supply chain.

A virtual token is created for each unit of material. These tokens pass through SAP software as the material is bought and sold along the supply chain. Manually tracking materials can be complicated, as there are often up to ten intermediaries between the mill and the consumer. SAP Green Token can be bought as an add-on to the purchasing systems that many companies already use.

We successfully conducted our first pilot of SAP Green Token in 2022, and a second pilot at UOI, working with four of our 12 independent mills to understand the support needed to implement the new system. These pilots have prepared us to potentially scale up in 2024.

Monitoring deforestation

NDPE dashboard

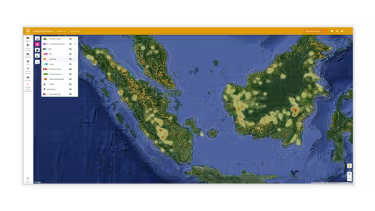

Our No Deforestation, No Peat Conversion, No Exploitation (NDPE) dashboard is a one-stop interactive platform through which we can monitor more than 20 million hectares of oil palm concessions, over 2,000 mills in our universal mill list, and the 28,000 smallholders we have mapped so far. It also includes supply chain linkage information to understand sourcing risk and compliance with the deforestation-free policy.

The sustainability compliance information of our suppliers is included, while Google Earth satellite images are embedded within the dashboard and continually updated, and deforestation alerts and grievances are also channelled into it. We obtained the concessions in our dashboard directly from our suppliers and via our partnership with Earthqualizer - it has one of the largest and most accurate data sets of palm oil concessions in the industry. This allows us to detect issues quickly and prioritise areas in which to support engagement in sustainable production and protection.

We are working on the complete digital forest footprint for our global palm oil supply chain, the next stage in our commitment to transparency. We are adding further data layers to the dashboard, and plan to integrate our other four in-scope commodities into it.

We are proud of our progress, but we understand that we still have work to do. We are excited to continue this journey towards making sustainability commonplace in the palm oil supply chain.

Content provided by third-parties may not meet our desired accessibility standards.

Javascript is required for this feature.